Trapping analytes with carbon nanotubes sponges

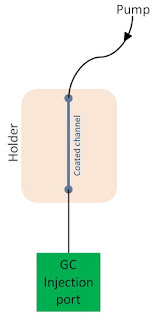

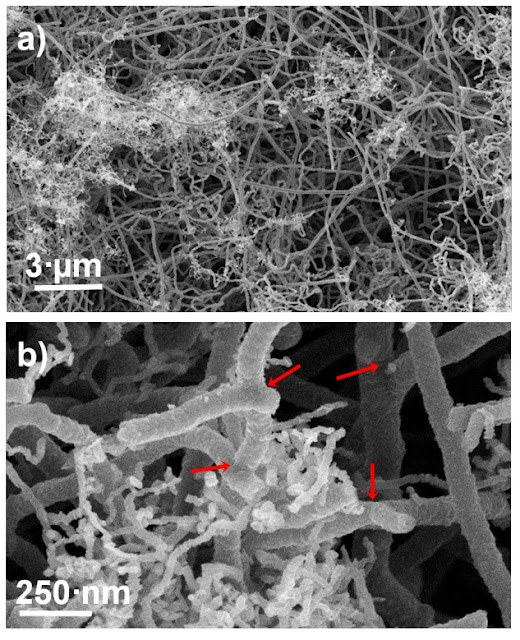

Carbon nanotubes sponges are three dimensional structures formed by the random self-assembly of these nanostructures during their synthesis. They are produced by the classical chemical vapor deposition method simply using special catalysts like ferrocene. The structure of an sponge can be observed in Figure 1A which shows a scanning electron micrograph of the bulk material. A closer view (Figure 1B) reveals how the nanostructures are interconnected(1). The sponges are characterized by a high superficial area (up to 100 m2/g), high porosity (derived from the 3D structure) and low density. From the chemical point of view they are superhydrophobic, property that has been exploited in some applications, such as the recovery of oil from water or the treatment of environmental waters. Figure 1. SEM micrographs of carbon nanotubes sponges at two magnifications. Reproduced from reference 1 Researchers from the Shandong Academy of Sciences and the Wuhan University of Technology have